Abrasion Resistant Materials and Wear Strips

Titanium Diffusion Hardening Creates a Superior Bearing Surface

PREVENT WEAR, EXTEND LIFE AND REPAIR DAMAGE WITH P54 AND KARON™ WEAR STRIPS

A wear strip is a material used to prevent metal-to-metal wear, wear against non-metallic materials, and fretting damage from sliding or rubbing surfaces. Wear strips are also used in applications where impact resistance is required or under edge loading conditions.

Protect Against Heavy Abrasion and Excessive

Amounts of Contaminants

End market environments for such applications include:

- Engine nacelles and thrust reverses

- Wing flap carriage assemblies

- Machine Tools

- Any application prone to fretting damage and wear

Custom Cut and Bonded to Your Needs

Kamatics wear strips are made from either KAron V or P54 material, and are available in a wide range of thicknesses and can be custom cut to fit your application.

ABRASION RESISTANT MATERIALS AND WEAR STRIPS RESOURCES

OTHER EXCEPTIONAL KAMATICS PRODUCTS

Spherical & Link Bearings

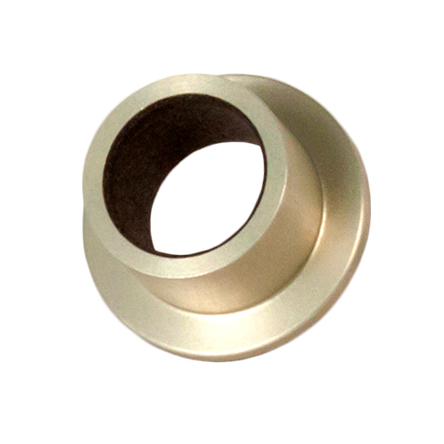

Bushings and Journal Bearings

Track Rollers and Needle Rollers

Flexible Drive Systems