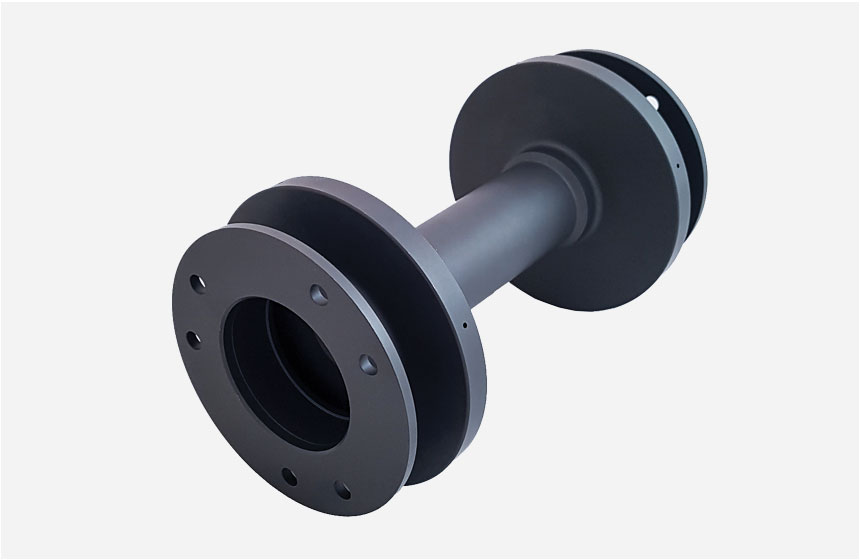

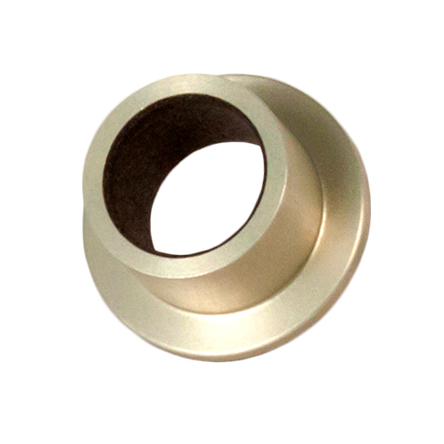

Our industry leading self-lubricating liner systems can meet the needs of applications across industries, including aerospace, marine, hydropower and space vehicles.

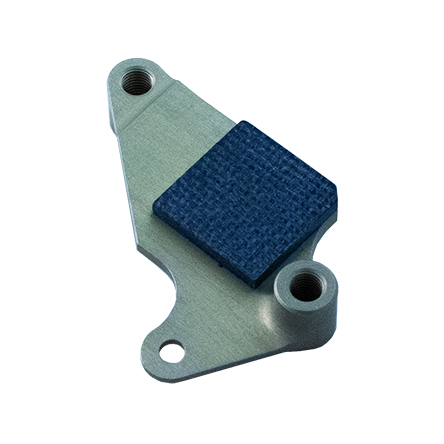

Learn more about the varieties of our KAron™ material, each of which has been developed to meet a wide range of environment, load, and wear conditions.